Solving the Challenges of a Complex Cardiac Diagnostic Device

Case Study: Manufacturing an Intricate Atrial Fibrillation Diagnostic Device

Overview

SMC partnered with an OEM to manufacture a highly complex atrial fibrillation vascular catheter capable of detecting 64 AFib signals simultaneously through a global array. The device integrates these signals to deliver cutting-edge cardiac diagnostics, requiring extreme precision, micro-assembly expertise, and tightly controlled material processes.

The Challenge

The Mapping Catheter program presented significant technical and manufacturing hurdles due to the device’s micro-scale circuitry and stringent performance requirements. Key challenges included:

- Microscopic, high-density circuitry requiring exceptional precision

- Redesigned device architecture focused on sustainable manufacturability

- Delicate, highly flexible components requiring skilled manual assembly

- Materials that demanded narrow, tightly controlled process windows

- Custom-built programming tools for circuit analysis and verification

- Documentation-heavy qualification and verification processes essential for device reliability

The Solution

SMC developed and executed a comprehensive manufacturing strategy combining skilled craftsmanship, advanced technology, and scientific material insights. The solution included:

- A broad-based operator training and assessment program to support highly specialized manual assembly

- Progressive surface texture modifications to improve performance

- Advanced welding technology delivering high reliability

- Micro-soldering processes optimized for copper bonding

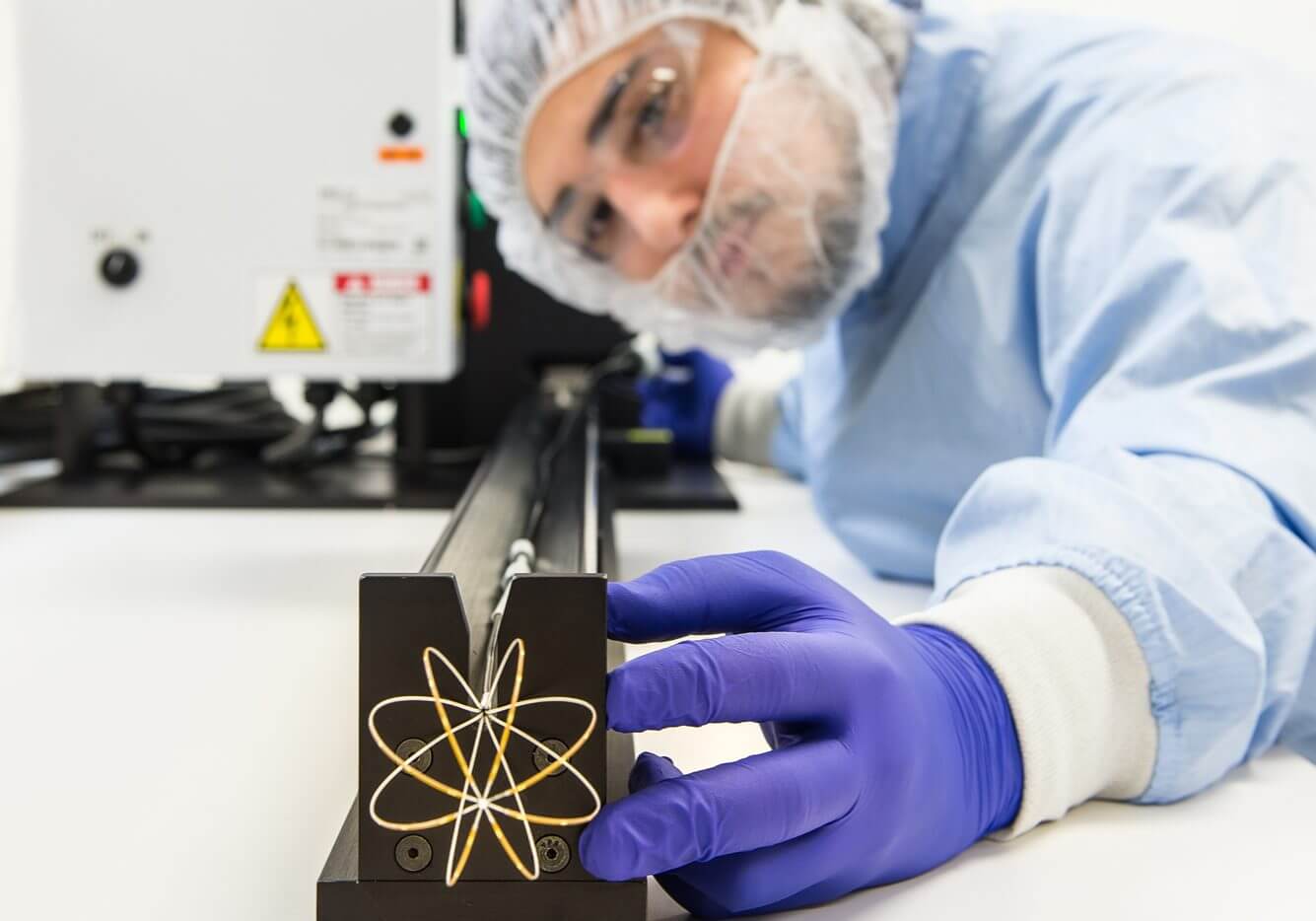

- Customized laser housing for enhanced precision

- Use of research to refine alloy balance for improved functionality

- Advanced adhesive application systems to improve quality and repeatability

- Improved reflow control for consistent, reliable connections

- A custom-built circuit analyzer to evaluate circuit integrity and ensure robust electrical performance

The Results

SMC’s engineering, materials, and micro-manufacturing expertise enabled the successful commercialization of a highly advanced cardiac mapping catheter. The collaboration delivered:

- A fully manufacturable, highly intricate device capable of capturing 64 AFib signals

- Improved assembly reliability and repeatability through advanced welding, soldering, and adhesive systems

- Enhanced material performance and circuit integrity through controlled processes and custom testing tools

- A trained, validated assembly workforce equipped to build a device of exceptional complexity